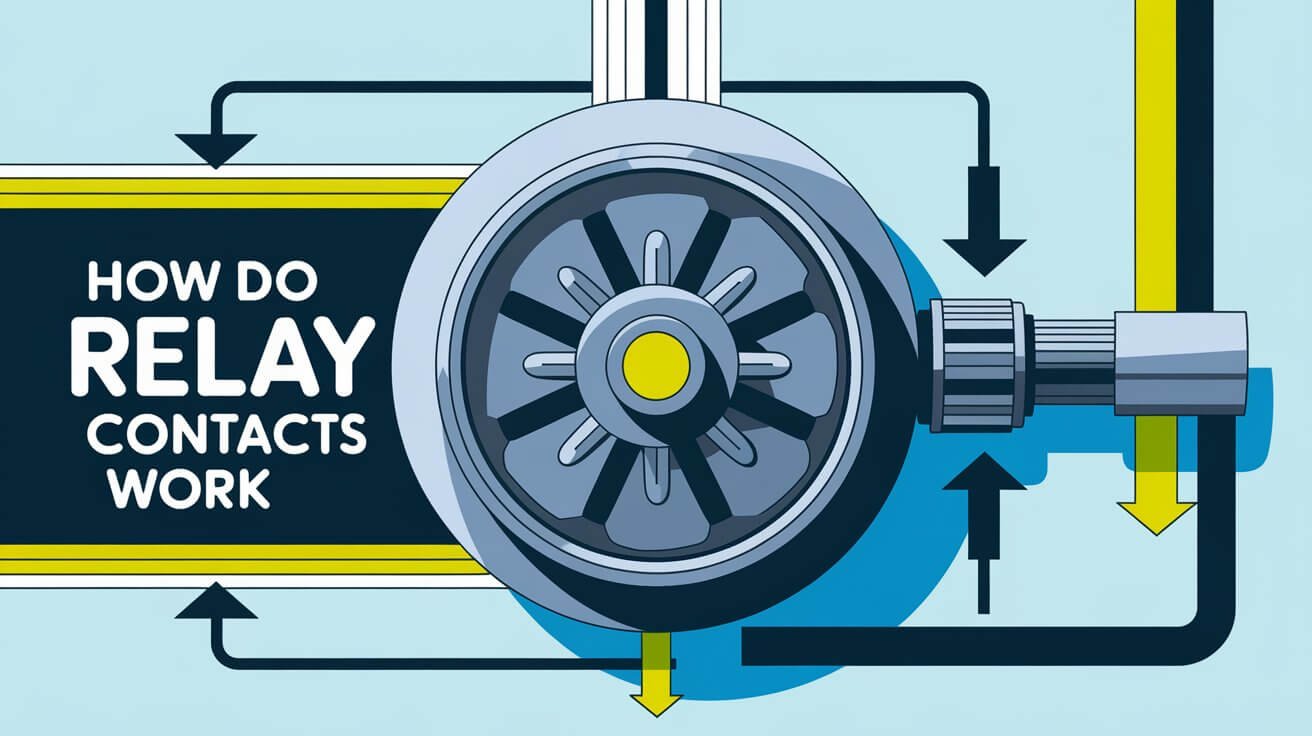

Relay contacts are key parts of relays. They act as an electrical switch, connecting control circuits to power circuits. They are used in many areas, like cars, appliances, and lights. Relays can handle big currents with just a little electricity, making them both reliable and efficient.

A relay is a switch that works with electricity. It uses an electromagnet to move its internal contacts. These contacts are the heart of relays, making them quick and dependable. They help protect equipment from too much current or voltage, which is why they’re so important in many fields.

Basic Structure of Relay Contacts

Relay contacts are key in electrical systems, letting current flow between two points. They have an electromagnet, a switch, and mechanical parts. These parts change the switch’s state when the electromagnet is turned on. This setup controls electrical circuits well, making relays essential in many areas.

The performance and life of relay contacts depend on the materials and setup. Silver, gold, and their alloys are often used because they conduct well and last long. The setup, like normally open (NO) and normally closed (NC) options, also matters a lot.

Contact Points and Their Components

Contact points are the core of relay contacts, where current flows. The moving and fixed contacts work together. They are usually made from materials like silver or gold to reduce energy loss and ensure reliable operation.

Types of Contact Materials

The material choice affects relay contacts’ performance and life. Some common materials are:

- Silver: Known for its high conductivity and resistance to corrosion

- Gold: Offers high conductivity and resistance to corrosion, making it suitable for high-reliability applications

- Copper: A cost-effective option with good conductivity, often used in low-voltage applications

Contact Configuration Options

The contact configuration affects how the relay acts in a circuit. Common setups include:

- Normally Open (NO): The contact is open when the relay is de-energized

- Normally Closed (NC): The contact is closed when the relay is de-energized

Knowing about relay contacts’ structure, including contact points, materials, and setups, is key for designing efficient electrical systems. By picking the right materials and setup, engineers can make relays work reliably and efficiently in many applications.

| Characteristic | Description |

|---|---|

| Maximum Switching Voltage | The maximum voltage allowed for opening/closing a relay contact |

| Maximum Switching Current | The maximum current permissible for opening/closing a relay contact |

| Maximum Switching Power | The maximum power capacity for opening/closing a relay contact |

Physical Principles Behind Relay Operations

Relays work on the principle of electromagnetic induction. A coil around a magnetic core creates a magnetic field when current flows through it. This field is key for moving the contacts.

The coil, magnetic core, and armature are involved. When the coil gets power, it makes a magnetic field. This field pulls the armature, moving the contacts. The return spring keeps the contacts in place when power is off.

Important aspects of relay operation include:

- Electromagnetic induction: The principle behind the magnetic field creation.

- Magnetic field: The field made by the coil, affecting the armature.

- Contact actuation: The movement of contacts due to the magnetic field.

Knowing these principles is vital for designing and using relays in electrical systems. The efficiency of a relay depends on the magnetic field, armature, and return spring. Electromagnetic induction is a key factor in how relays work.

Contact States and Switching Mechanisms

Relay contacts can be in different states. Knowing these states is key for designing and fixing relay circuits. When a relay is off, its contacts are either open or closed by default. The contacts switch when the coil turns on, changing their state.

For example, when the coil is on, power moves from the closed to the open pin. This shows how contacts switch and change states.

Relays use make-before-break and break-before-make to switch. Make-before-break connects first, then breaks. Break-before-make breaks first, then connects. These methods prevent damage and ensure reliable switching.

Contact bounce is another issue. It makes contacts wobble between open and closed before settling. This can mess up circuit performance and reliability.

Normally Open vs Normally Closed Contacts

Normally open contacts close when energized. Normally closed contacts open when energized. The choice depends on the application and desired outcome.

Knowing the difference between these contacts is essential for making efficient relay circuits.

Make-Before-Break and Break-Before-Make Operations

Make-before-break and break-before-make are two switching methods. Make-before-break connects new before breaking old. Break-before-make breaks old before connecting new.

These methods are vital for avoiding damage and ensuring reliable switching.

Contact Bounce and Its Effects

Contact bounce makes contacts wobble between open and closed before settling. This can harm circuit performance and reliability.

Understanding bounce and its effects is critical for designing and fixing relay circuits.

| Contact Type | Description |

|---|---|

| Normally Open (NO) | Closed when the relay is energized |

| Normally Closed (NC) | Open when the relay is energized |

| Make-Before-Break | Establishes a new connection before breaking the old one |

| Break-Before-Make | Breaks the old connection before establishing a new one |

Current Flow Through Relay Contacts

Relays help control high current circuits with a low current signal. The current a relay can handle is key to its use. Contact resistance also matters, as it can cause voltage drops and heat.

Manufacturers use arc suppression to lessen voltage spikes when contacts move. This protects the relay and other parts. Knowing how current flows through relay contacts helps designers pick the right one for their needs.

| Relay Type | Current Capacity | Contact Resistance |

|---|---|---|

| General Purpose Relay | 2A to 30A | 50 to 120 ohms |

| Reed Relay | Up to 10A | 10 to 50 ohms |

Designers consider current capacity, contact resistance, and arc suppression to make efficient systems. Relays are important in many areas, like industrial automation and home appliances. Understanding how they work is key to safe and efficient use.

Common Relay Contact Configurations

Relay contact configurations are key to a relay’s function in a circuit. The main types are Single Pole Single Throw (SPST), Double Pole Double Throw (DPDT), and multi-pole relays. These setups decide how the relay switches power between different circuits.

A SPST relay is simple, with just one input and one output. It’s great for basic on/off tasks. But, a DPDT relay can handle two circuits at once. This makes it perfect for complex tasks where many circuits need control.

Multi-pole relays offer even more, controlling many circuits. They’re great for industrial control, cars, and home systems. Here’s a quick look at the different relay types:

| Configuration | Description |

|---|---|

| SPST | Single Pole Single Throw, basic on/off functionality |

| DPDT | Double Pole Double Throw, controls two separate circuits simultaneously |

| Multi-pole | Expands the relay’s switching capabilities for complex applications |

In short, knowing about SPST, DPDT, and multi-pole relays is vital. It helps pick the right relay for any job. By matching the circuit’s needs with the right relay, you get reliable and efficient results.

Protection Features in Modern Relay Contacts

Modern relay contacts have special features to avoid damage from arcing and voltage spikes. Snubber circuits are used to stop arcs and make contacts last longer. Metal-oxide varistors (MOVs) also help by soaking up voltage spikes, keeping the relay and other parts safe.

Coil suppression is another key feature. When the relay coil loses power, it can create voltage spikes that harm the circuit. Flyback diodes are used to block these spikes, protecting the circuit. Resistors or diodes are added to the coil to stop or lessen these spikes.

Some main protection features in modern relay contacts are: * Arc suppression to prevent damage from arcing * Coil suppression to prevent voltage spikes * Contact protection to extend contact life * Use of snubber circuits and MOVs to absorb voltage spikes * Use of flyback diodes to suppress voltage spikes

| Protection Feature | Description |

|---|---|

| Arc Suppression | Prevents damage from arcing |

| Coil Suppression | Prevents voltage spikes when the relay coil is de-energized |

| Contact Protection | Extends contact life and prevents damage |

Relay Contact Applications in Circuit Design

Relay contacts are key in many fields like industrial control, automotive, and home automation. In industrial settings, they help control big machines with small signals. For example, a microcontroller like Arduino can control a lamp’s on/off state with an electrical relay.

In cars, relays manage headlights, motors, and more. Automotive relays, like ISO relays, have special features for the car industry. Home automation systems also use relays to control lights and appliances, making life easier and saving energy.

Industrial Control Systems

Industrial control systems rely on relays to manage equipment safely and efficiently. They control motors, pumps, and other big devices, essential for automation.

Automotive Applications

Car relays handle tasks like headlights and taillights. They’re built to withstand high temperatures and vibrations, meeting car industry needs.

Home Automation Systems

Home automation uses relays to control lights and appliances. This makes managing your home easy and energy-smart. Relays help with lights, thermostats, and security, automating your home.

| Application | Relay Type | Features |

|---|---|---|

| Industrial Control | Electromagnetic Relay | High-power control, low-power signal |

| Automotive | ISO Relay | Resistor protection, standardized terminal pattern |

| Home Automation | Solid-State Relay | Compact design, low power consumption |

Troubleshooting Relay Contact Issues

When you face relay contact problems, finding the main cause is key. Issues like contact wear, coil failure, and wrong wiring are common. Start by checking the relay switch’s voltage and current rating. Make sure it matches your application’s needs.

Coil failure can happen due to temperature changes, too much voltage, or wrong voltage connections. Contact problems might stem from welding, increased resistance, or too much load. Try cleaning oxidized surfaces, using solvents, or replacing welded contacts to fix these issues.

Here are some steps to troubleshoot relay contact problems:

- Check if the voltage is right and wiring is correct

- Make sure the resistance between terminals 30 and 87 is under one ohm when energized

- Watch for continuity from 30 to 87 and then from 30 to 87a to see the switch working

- Use a multimeter to check voltage and continuity in the wiring

Using these troubleshooting steps and knowing common causes, you can find and fix relay contact problems. This ensures your equipment works well and avoids damage.

Endnote

Relay contacts are key in electrical and electronic systems. They make switching reliable and flexible across many industries. This includes cars, factories, home gadgets, and power systems.

They control electricity, manage motors, and protect systems from power issues. Despite new technologies, relay contacts remain vital. They handle big currents and last long, making them a must in circuit design.

Now, you know more about relay contact operation, electrical switching, and contact reliability. Use this knowledge to improve your work. It will help make systems safer, more efficient, and reliable.

Commonly Asked Questions

What are relay contacts, and what is their fundamental role?

Relay contacts are electric switches that connect control circuits to power circuits. They let us control big equipment with small signals.

What are the essential components that form the contact points in relay contacts?

Relay contacts have moving and fixed parts. The materials used, like silver or gold, affect how well they work and last.

How do relay contacts function based on the principles of electromagnetic induction?

When energized, the coil in a relay makes a magnetic field. This field moves the armature, opening or closing the contacts. A spring keeps the contacts in place when the coil is off.

What are the different states that relay contacts can assume, and how do they switch between these states?

Contacts can be open (NO) or closed (NC). They switch in different ways, like make-before-break or break-before-make. Sometimes, they might bounce during switching.

How does current flow through relay contacts, and what factors affect it?

The size and material of contacts affect how much current they can carry. The resistance of contacts can cause heat and voltage drop. Techniques like arc suppression help protect them during high currents.

What are the common relay contact configurations and their applications?

Contacts come in SPST, DPDT, and multi-pole types. Each type can switch in different ways, making them useful for many tasks.

What protection features are incorporated into modern relay contacts?

Modern contacts have features like snubber circuits and metal-oxide varistors (MOVs). These help prevent damage from arcing and voltage spikes.

How are relay contacts used in different applications?

Relay contacts are used in many places. They help control big equipment in factories, cars, and homes with small signals.

What are some common issues that can arise with relay contacts, and how can they be diagnosed?

Issues like wear, resistance, and coil failures can happen. To fix these, test the contacts, coil, and wiring. Make sure everything is working right.